Use of Phase Change Material as Thermal Buffer for Indoor Comfort

Research has demonstrated application of phase change material (PCM) to buffer daily temperature swings for improved indoor comfort during seasonal extremes. PCMs are qualified for AlabamaWISE incentives.

A freeze pack encapsulates phase change material to keep food cold.

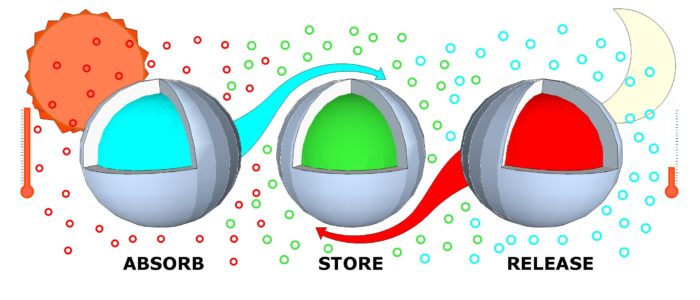

Phase Change is the scientific way to say “freezing” or “vaporizing” – it is a change of state for any material from solid to liquid or from liquid to vapor. Application of phase change takes advantage of the capacity for the material to store or release energy during the phase change and maintain a steady temperature.

The most common use of phase change material is ice for its considerable capacity to absorb heat as it melts, or changes phase. As it melts, the temperature remains a constant 32 degrees. This thermal storage effect has many applications for cold storage systems beyond keeping a glass of summer tea cold.

Packaged ice packs encapsulate a phase change material for use with coolers and lunch boxes. Placing a frozen ice pack in a lunch box will stabilize the food temperature for several hours as the ice changes phase from solid to liquid. The ice pack can be re-used over and over.

What if we made ice packs with a material that “freezes” at 74 degrees and used it to keep buildings cool during summer heat as the encapsulated material melts? Could we use the same stuff to help keep buildings warm in winter as an encapsulated material buffers cooling temperatures? Now you can.

Encapsulated phase change material is placed on the interior side of the insulated wall before drywall.

Building scientists have demonstrated how to design homes using encapsulated phase change material to manage indoor comfort from temperature extremes by placing encapsulated phase change material on the interior side of insulated walls, ceilings and floors. The melting point of the phase change material is close to room temperature, so it will melt or freeze within the indoor comfort zone, which typically ranges from 68 degrees to 78 degrees.

A well-insulated building maintains indoor temperature because it resists heat movement. The thicker the insulation, the longer it takes for heat to penetrate the insulation, but most homes have walls 4 to 6 inches thick, limiting the maximum insulation value of the wall to R-19 in most cases, and causing comfort problems and straining your heating and cooling system during daily summer highs and winter lows.

The phase change material acts a thermal sponge to absorb summer heat during the hour of peak temperatures by melting. This excess heat is flushed by the air conditioning system over several hours and the phase change material returns to a solid state, ready to absorb the next days peak heat.

Traditional building designs, such as adobe, also buffer temperature extremes absorbing and releasing stored heat, but this approach requires massively thick walls. Phase change materials can manage similar energy loads with much less volume – a necessity when working with the constraints of 2 x4 or 2 x 6 wall framing. Research on thermal mass walls at Oak Ridge National Lab demonstrated thermal performance and energy benefits for placing thermal mass on the interior of well-insulated walls in mixed-humid climate of the southeast.

Phase change material can be especially helpful during winter months for homes with heat pumps. Heat pumps are highly efficient electrical heating systems for the relatively mild winters of Alabama. The dis-advantage for heat pumps is on the coldest winter nights when heat is needed most. As the name implies, heat pumps capture outdoor heat and “pump” it into the home. On the coldest nights, there just isn’t much heat to capture at a time when demand is greatest, so most systems use electric back-up heat to make up the difference.

Phase change material (PCM) can be characterized as a thermal sponge to absorb heat spikes during the cooling season and as a thermal battery during heating season to buffer living space from temperature extremes that penetrate the home’s exterior insulation.

Phase change material can buffer against the lowest night temperatures because they store heat energy by melting as the heat pump runs during the day when outdoor temperatures are higher. Over night the material will buffer indoor temperatures from the cold as it once again changes phase from liquid to solid by releasing stored heat into the home.

PCMs can achieve peak load reductions of 35% for cooling and 26% for heating.

Effective use of phase change material in residential application requires a design based on computer modeling with software such as EnergyPlus and a decision about where indoor temperature set points to ensure the melting/freezing point of the phase change is closely matched to indoor temperature.

Phase Change Material qualifies for the AlabamaWISE program loans and incentives.

Comments are closed.